Amer, Jaipur, Rajasthan

- GST NO. : 08AFUPJ7289M1ZA

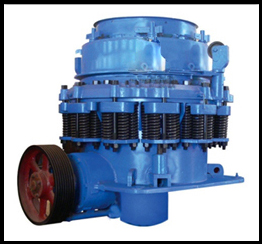

Cone Crusher Manufacturers Jaipur- How This Machine Can Increase Your Productivity

Posted by Admin on February, 18, 2021

Cone crushers are one of the utmost extensively used types of stone crushers. They are used to decrease the size of large rocks and ores into smaller pieces and granules. They are used in various industry; such as mining, metallurgical, constructive, and chemical & phosphate industry. They may also be employed in social/governmental projects such as railway makeover and road building. You can avail them by ordering to the Cone Crusher Manufacturers in Jaipur.

Components used in the cone crusher machines

A Cone crusher is a very complicated machine and contains lots of components, but its principal structure remains the same, consisting of:

Principal Shaft: It is used to stand the mental. It is maintained by the bearing at the base and is secure beneath the mantle. Driven by the warped bevel gears in the countershaft, the principal shaft itself does not rotate; but it is essentially housed in a frame that rotates.

Counter Shaft: The countershaft creates rotary motion in the cone crusher. The gear energies the housing of the eccentric principal shaft.

Springs: Big springs are part of the security mechanism in cone crushers, which avoids the occurrence of damage in the course, due to stiffer and more-solid-rocks. They smear downward pressures on the upper frame to stop harder-rocks that cannot be crushed, from moving on and damage the crusher by entering the cavity.

Manganese Mantle: The Manganese-mantle is one of the crushing surfaces of the machine in question, i.e., the Cone

Crusher. It alternates in a spherical movement-pattern by an eccentric lobe like an ice-cream cone machine fills the material inside the cones!

Functions of the cone crushers

The working principles of the Cone Crusher are like to gyratory crushers, with more of a similar zone and less steepness in the crushing chamber. This one breaks the rocks by crushing and squeezing them between the eccentrically gyrating spindles and enclosing concave hopper. The gyrating spring is protected by the wear-resistant mantle and the concave hopper is shielded by the bowl liner or manganese concave.

The crushing hollow is the area between the fixed and the movable cone. When the rock or ore pass in the Cone Crusher from the top, it stops in the upper area and gets squeezed between the bowl liner and the mantle. Big pieces are broken and permitted to fall to the lower position where they have smashed again. This procedure lasts until these pieces are small adequate to escape through the narrow opening accessible for these pieces at the lowest part of the machine i.e. the bottom area.

Benefits of the cone crusher machines supplied by the Cone Crusher Manufacturers in Jaipur Rajasthan

Cone crushers are one of the utmost advanced and effectual types of rock crushers. They offer many benefits, including but not limited to, the big crushing ratio, thin and uniform product size, low power consumption and good gritty products. They involve energy-saving ultra-fine broken elements of rock. They use covered crushing principle and comprise of a wide product range. Their cavity clearance is added suitable than any other type of crusher-type machine. The use of heavy-duty rock, diameter shaft and a distinct lubrication system confirms the reliability and durability of the machine.

This entry was posted on February, 18, 2021 at 14 : 56 pm and is filed under Cone Crusher. You can follow any responses to this entry through the RSS 2.0 feed. You can leave a response from your own site.

Search

Recent Posts